NINGBO MENGTING OUTDOOR IMPLEMENT CO., LTD was established in 2014, which is developing and producing in outdoor headlamp lighting equipment, such as usb headlamp, waterproof headlamp, sensor headlamp, camping headlamp, working light, flashlight and so on. For many years, our company has capability to provide the professional design development, the experience of manufacture, the scientific quality management sysment and the strict work style. We insist on the enterprise sprit of innovation, pragmatism, unity and intergrity. And we adhere to use the advanced technology with excellent service to meet the individual needs of customer. Our company has established a series of high-quality projects with the principle of “top-grade technique, first-rate quality, first-class service”.

*Factory direct sale and wholesale price

*Thorough customised service to meet the personalized demand

*Completed testing equipmet to promise the good quality

When you are in the outdoor night, relying on the light of the headlamp forward, have ever thought that behind this light, is a strict quality inspection process in the factory escort? In our factory, the quality inspection of outdoor headlights is not a simple formality, but a persistent pursuit of the ultimate quality.

Each outdoor light factory has its own quality system, and we also have it, including product testing in the early stage of production, raw material inspection, training and inspection during assembly and production, aging test after assembly, full inspection and test before packaging, verification and inspection of packaging materials, and finished product inspection after packaging.

Pre-production preparations:

Before the production of headlight, we will conduct comprehensive testing on samples to ensure that the production can meet the overall demand.

As the basis of the headlamp quality, the factory adopts the advanced integral ball test system. The system can accurately measure the key indicators such as the total light flux and illumination uniformity of the headlamp.

When measuring the optical flux (Lumen), the measurement results are more reliable, and the integral sphere can reduce and remove the measurement error caused by the shape of the light, the divergence angle, and the difference in responsiveness at different positions on the detector. When the integral sphere is matched with the spectrometer, the optical output hole of the integral sphere is connected to the incident port of the spectrometer through the optical fiber, which greatly improves the reproducbility of the measurement.

The two complement each other to ensure that the factory LED headlights, not like ordinary headlights accompanied by the use of brightness reduction, but the use of the corresponding detection instrument, to ensure that the constant lighting technology headlights show better performance, can remain unchanged during the use of brightness, for outdoor work or sports from beginning to end to provide a good vision.

Raw material inspection:

The quality of raw materials directly affects the quality of the headlamp. By inspecting raw materials, we can promptly identify and remove substandard materials, preventing them from entering the production process, thus ensuring product quality and safety. Materials such as ABS and PC, which are primarily used in outdoor headlamps, all undergo rigorous inspection before being accepted for production.

Training and inspection during assembly and production:

Pre-production training for headlamp manufacturing is extremely important. We have detailed and professional product headlamp instructions, and all our workers undergo rigorous training. Through this training, employees gain a better understanding of the headlamp production process, become familiar with safety procedures, and have a clear grasp of both dry cell headlamp and rechargeable headlamps. Pre-production training also enables employees to self-check during production, reducing errors and improving efficiency.

In the production process, there will inevitably be some potential problems, such as circuit failure, unstable light source, insufficient heat dissipation, etc. The aging test helps to identify and solve these problems early by simulating the actual use conditions before leaving the factory, to ensure that the high-light headlights perform well in the hands of users.

Our factory has professional battery aging testing equipment, long time, multi-cycle charge and discharge test of headlamp batteries. Through aging testing, we are able to evaluate whether the headlamp can maintain stable performance during the long operation, thus improving the overall quality level of the headlamp.

The aging test can simulate the actual use situation, evaluate the reliability of high light headlights in different working conditions, and improve the user,trust in high light headlights.

Through the aging test, the possible problems can be found in time, to reduce the failure of strong light headlights in the hands of users, so as to reduce the cost of after-sales maintenance. This helps to enhance the brand reputation and enhance user satisfaction with bright light headlights.

At the same time, combined with the actual outdoor use scenarios, the power consumption in different brightness modes is simulated. Through these tests, we can not only ensure that the duration of the headlights meets user needs, but also ensure the stability and safety of the battery in long-term use.

Modern outdoor headlamp function is increasingly rich, our factory in the function test is not ambiguous. Each feature is tested repeatedly, from basic lighting functions, to flicker mode used to send emergency signals, to different brightness levels to adapt to various scenarios. Inspectors will frequently switch the headlamp function in different environments to ensure that the mode switch is smooth, no lag, no fault. For some high-end headlights equipped with intelligent dimming, red light mode (protect night vision) and other functions, is also a comprehensive and detailed evaluation, to ensure its practicality and reliability in actual use.

Headlight packaging inspection:

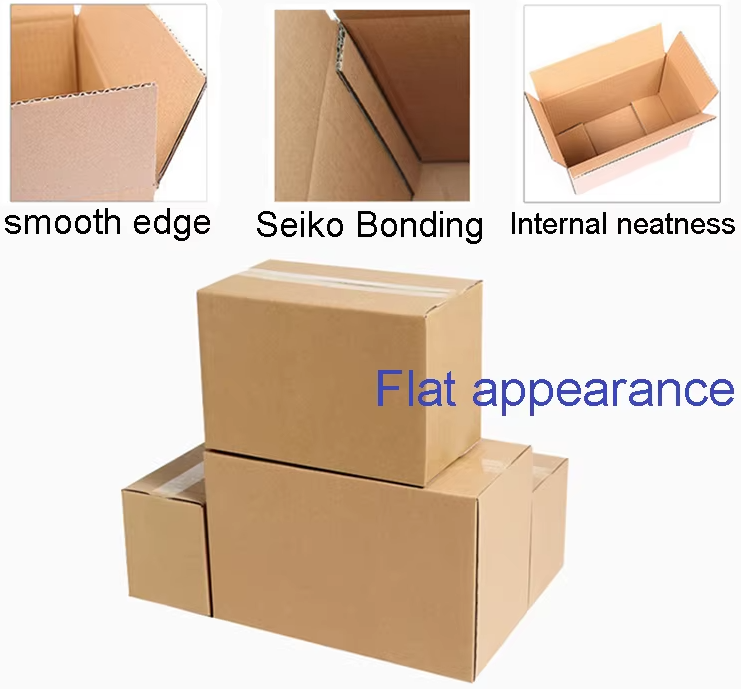

As customers place increasing emphasis on branding and packaging becomes more diverse, factories have also intensified their inspection of packaging. This includes thorough checks on the materials used, from the details of instructions to the printing content of color boxes, dimensions, the material of blister packs, the marking on inner and outer boxes, and the hardness of the material.

For printed products, it is required that the printed pattern/word is clear, without color difference, blur, break point, white exposure, overprint and other problems. The printed content should be complete, correct and free from text errors.

The size of the packaging material shall not exceed the tolerance ±2mm, so that the packaging material can perfectly fit the outdoor headlight product.

Product inspection:

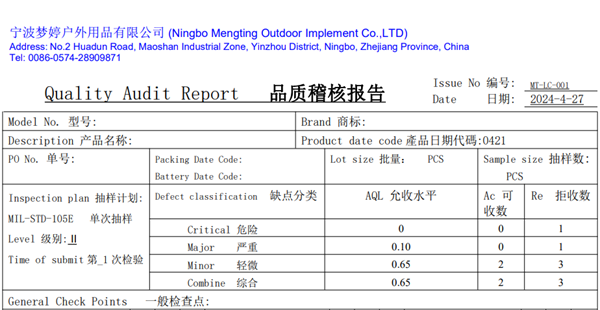

We have special quality inspection personnel for quality inspection,according to the proportion of sampling, the inspection contents including: product appearance, performance, accessories, packaging, etc., and submit a complete quality inspection report and bulk cargo photos to customers. All the products that have not been inspected are not allowed to be shipped, and only the qualified headlamps that have passed through the inspection can leave the factory.

Our finished products are also tested for durability. The durability test is also strict, in order to test the durability of the headlights, the factory uses drop test and vibration test equipment. Headlights are freely falling from different heights, simulating an accidental drop scene, while experiencing a high-strength vibration test, to test the strength of the shell material and the stability of the internal components. After many hardships, still intact headlamp, to set foot on the outdoor journey.

Brand and reputation: strict control, set up a quality benchmark

In our factory, the brand reputation is above all else. We know very well that every headlamp carries the trust of consumers. Therefore, from the purchase of raw materials to the delivery of finished products, the whole production process follows a strict quality control system. We have special quality inspection personnel for quality inspection, including: product appearance, performance, accessories, packaging, etc., and submit a complete quality inspection report and bulk cargo photos to customers. All the products that have not been inspected are not allowed to be shipped, and only the qualified headlamps that have passed through the inspection can leave the factory.

Each production link is responsible for a special person, and each inspection process has a detailed record. We actively collect market feedback, refer to the use of other outdoor enthusiasts, and constantly optimize product quality. It is this persistent pursuit of quality that makes our headlights win a good reputation in the market and become a trusted brand for outdoor enthusiasts.

When you buy the outdoor headlights produced by our factory, what you buy not only a lighting tool, but also a safety guarantee, a trust in the ultimate quality. We use a professional inspection process and ingenuity to light up a reliable headlight for your outdoor adventure.

WHY DO WE CHOOSE MENGTING?

Our company put the quality in advance, and make sure the production process strictly and the quality excellently. And our factory have passed the latest certification of ISO9001:2015 CE and ROHS. Our laboratory now have more than thirty testing equipments which will grow in the future. If you have the product performance standard, we can adjust and test to meet your need convinently.

Our company have manufacture department with 2100 square meters, including the injection molding workshop, assembly workshop and the packaging workshop which have equiped with completed production equipment. For this reason, we have effcient production capacity which can produce 100000pcs headlamps per month.

The outdoor headlamps from our factory are exported to the United States, Chile, Argentina, Czech Republic, Poland, United Kingdom, France, Netherlands, Spain, South Korea, Japan, and other countries. Because of the experience in those countries, we can quickly adapt to the changing needs of different countries. Most of outdoor headlamp products from our company have passed CE and ROHS certifications, even part of products have applied for appearance patents.

By the way, each process are draw up the detailed operating procedures and strict quality control plan in order to make sure the quality and property of the production headlamp. Mengting can provide various customized services for headlamps, including logo, color, lumen, color temperature, function, packaging, etc., to meet the personalized needs of different customers. In the future, we will improve the whole production process and complete the quality control in order to launch the better headlamp for the changing market demands.

10 years exporting & manufacturing experience

IS09001 and BSCI Quality System Certification

30pcs Testing Machine and 20pcs Production Equiment

Trademark and Patent Certification

Different Cooperative customer

Customization depend on your requirement

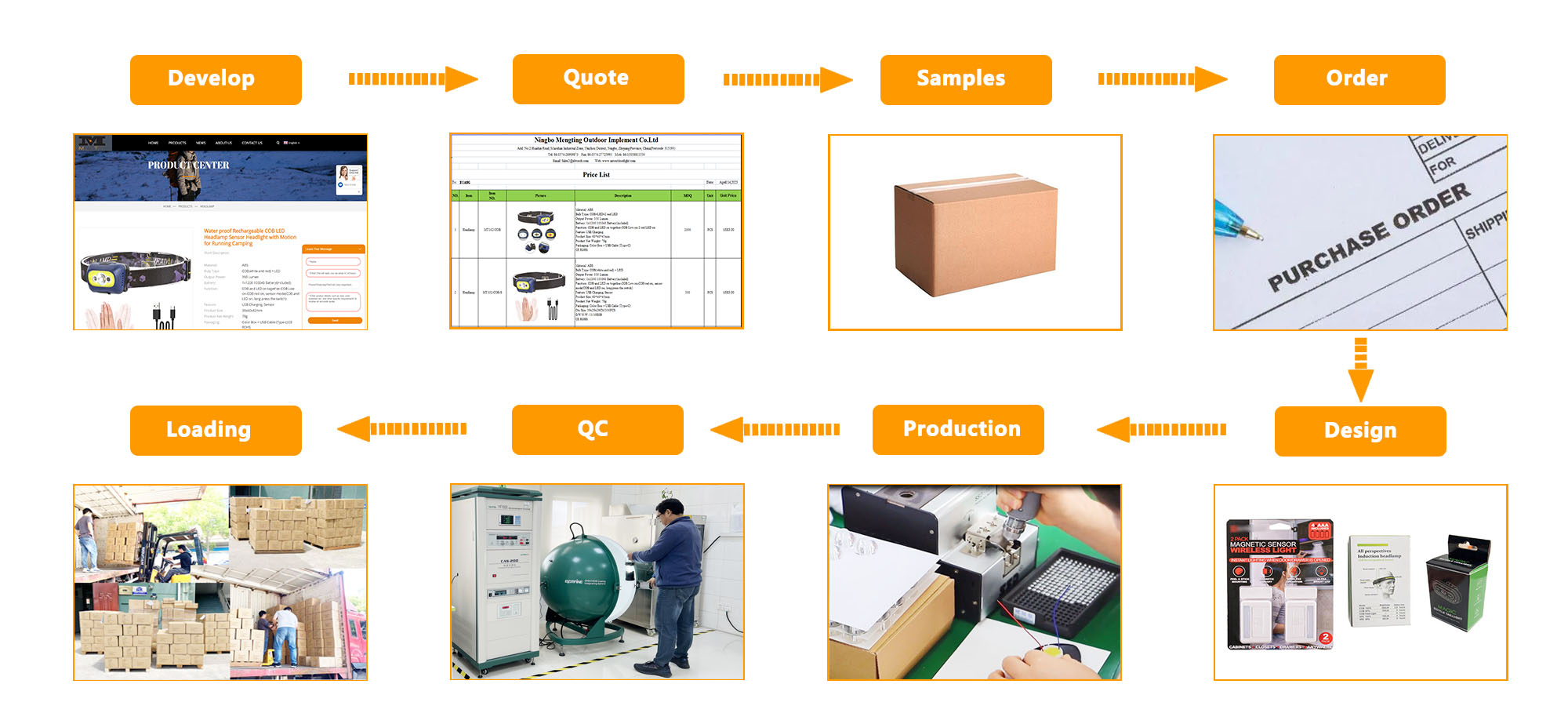

How we work?

Develop(Recommend ours or Design from yours)

Quote(Feedback to you in 2days )

Samples(Samples will be sent to you for Quality inspection)

Order(Place order once you confirmed Qty and delivery time,etc.)

Design(Design and make suitable package for your products)

Production(Produce the cargo depend on the customer’s requirement )

QC(Our QC team will inspect the product and offer the QC report)

Loading(Loading ready stock to client’s container)

fannie@nbtorch.com

fannie@nbtorch.com +0086-0574-28909873

+0086-0574-28909873